3D-printing has, without doubt, revolutionized the manufacturing industry. Thanks to this technology we are able to simply print out customized objects and parts, even if they present complex structures. Compared to other production techniques, such as injection molding -which, as the name already states- requires a previous construction of a mold- or machining, where blocks or sheets of material are cut into a desired shape, 3D printing allows so-called additive manufacturing. This means that objects are built by adding material together, instead of reducing it to a final shape. A previously designed digital 3D-Model of the wanted object serves the printer as a construction plan. Based on the CAD-model the printer builds the final object-usually layer by layer-, using materials such as metal, polymers or even ceramic.

Compared to other techniques, 3D-printing reduces costs and manufacturing time drastically. Changing the properties of the materials used for 3D printing allows us to produce cheaper prototypes, which enables us to detect design errors early and, consequently, reduce the risk of fault production.

Since the printed products are based on a digital model, they can easily be altered or modified. Instead of using one single mold for a serial production, we can personalize the items. Especially in the medical sector, 3D-printing has improved the life of many patients, for important prosthetic implants can now be adapted to each body individually.

Another huge benefit of 3D-printing is its scalability. Objects can be printed out in diverse sizes, using the same digital model. This way we can adapt objects to the spaces we have available, or form them to the exact proportion we want them in.

When Stämm decided to build a completely new device to optimize the manufacturing process of biotech products, we knew we had to look for a solution in 3D-Printing, for no other manufacturing technique allows us to build more complex structures. We wanted to imitate a natural environment for cells, inspired by the vascular system of our body or the capillaries that nurture plants, and at the same time reach a high production capacity. We wanted a large-scale microbioreactor.

For the printer, this meant creating an elaborated mingle of really tiny tubes and channels, capable of holding several liters of fluids. Even if it sounds contradictory, that ends up in printing large surfaces in very small pixel size.

As you can imagine, while scouting the market for a suitable machine, we couldn’t find a printer able to fit our demands.

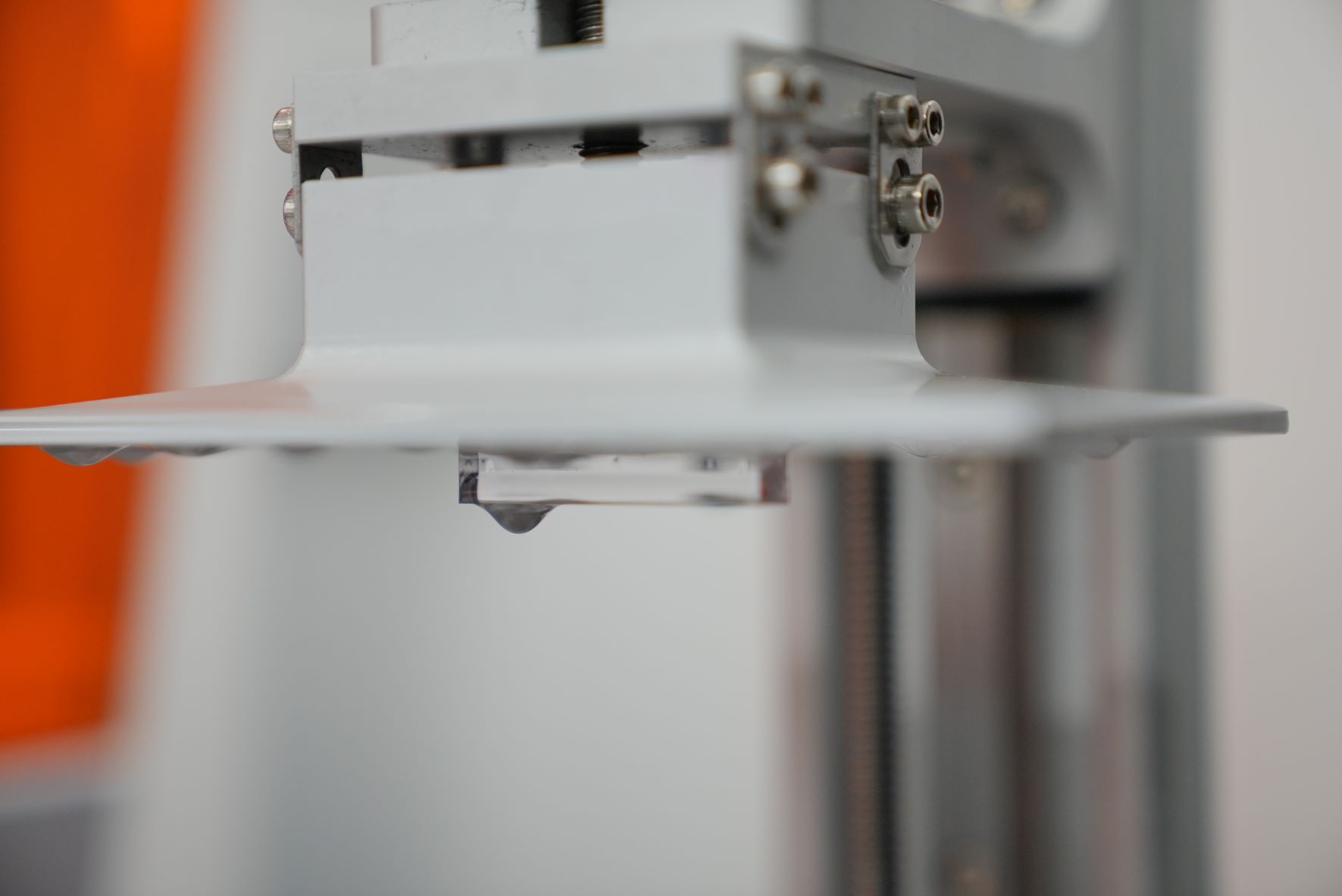

Surely, this first felt like a huge setback, but then we embraced developing our own printing device. Our amazing engineers, specialized in optics and 3D-Printing among others, came up with a whole new printing technology that combines the precision and versatility of laser-based printers with the capacity of simultaneously printing millions of dots. We call it the Brick-Printing Technology and we are very proud of our first in-house printer, equipped with the optical system to realize our project : The Sclereid.

By Hannah Kreher