Reinventing 3D printing

to unleash the full

potential of microfluidics

KämbiumWhile building our Bioprocessor, we stumbled upon an obstacle: there was no machine that could materialize a microbioreactor. According to its complexity, we concluded 3D printing was the appropriate techonology.

Building a large-scale microbioreactor sounds like an oxymoron, yet it’s exactly what we needed to achieve. We had to print large surfaces without compromising the size of the pixels.

Analyzing the 3D-printing technologies available on the market, we learned that the ones that could reach smaller pixel sizes were not optimized to maximize the working surface, and vice-versa. Our only option was to build it ourselves, and so we did.

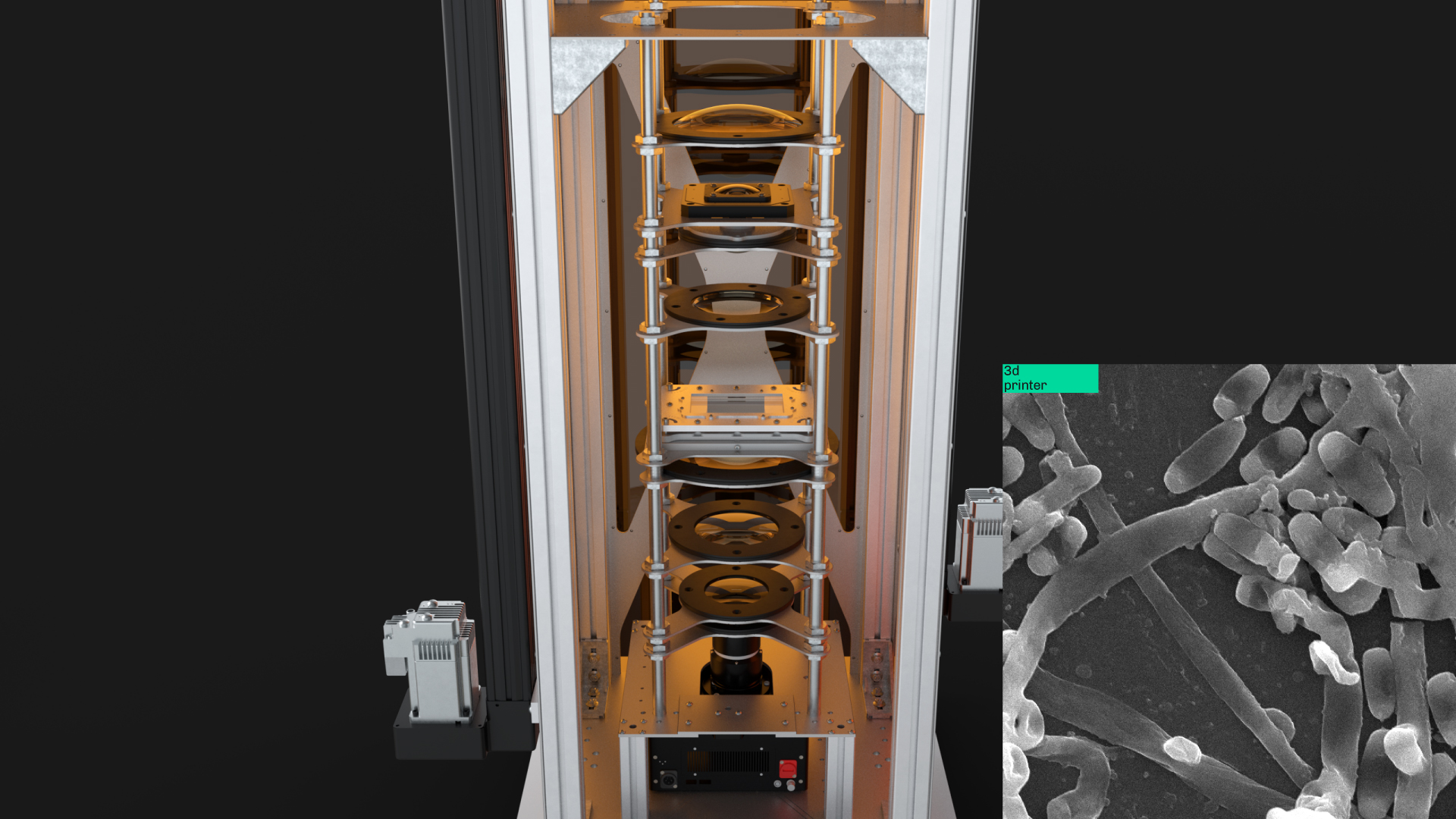

After much research and hard work, we developed our Brick Printing Technology, which leverages the benefits of printing millions of dots simultaneously with the precision and versatility of laser-based printers. We then proceeded to design an optical system that would allow us to build the first 3D printer with brick printing technology: The Sclereid.

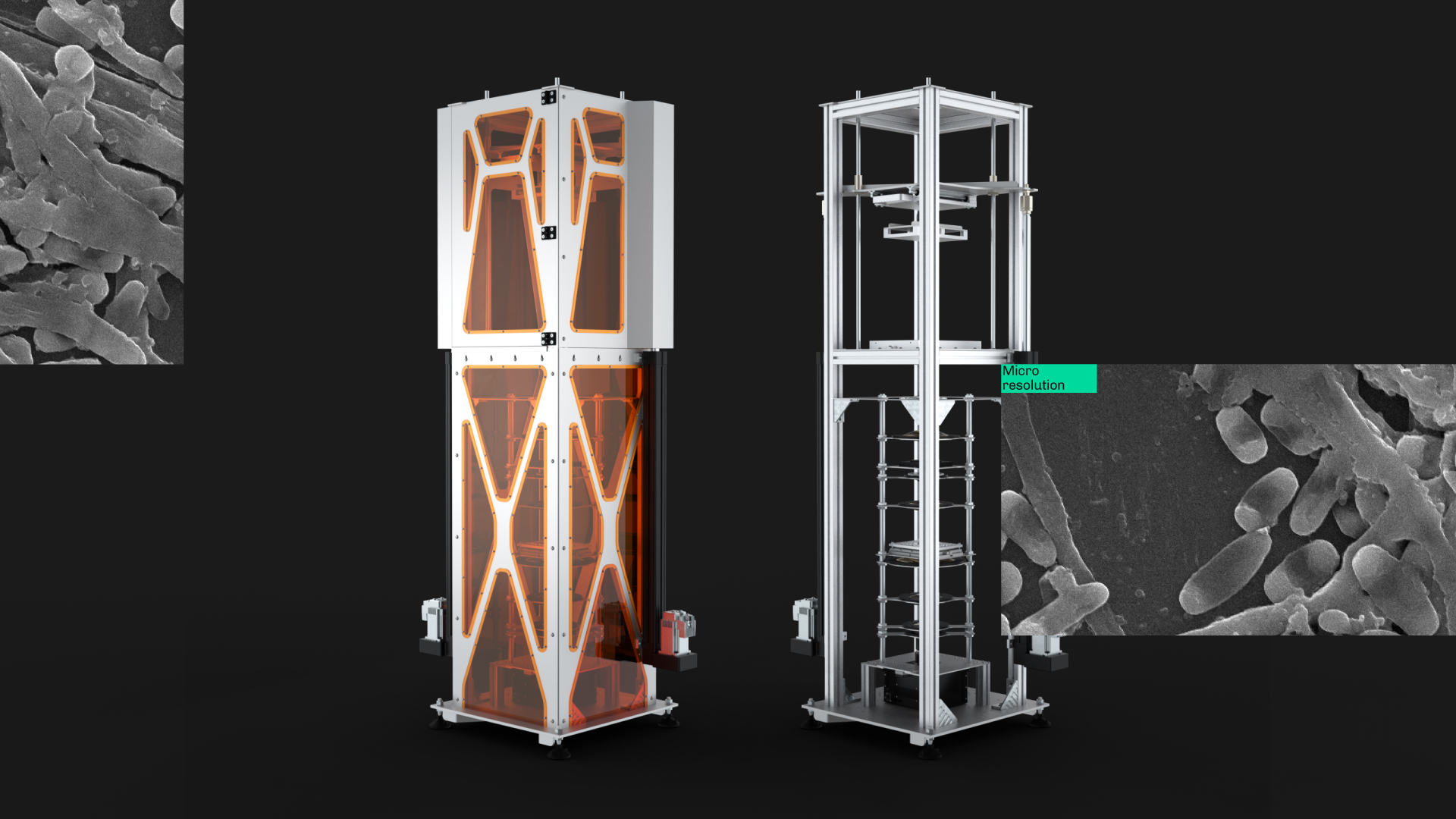

The Sclereid

Our first model features a temperature-controlled sterile cabinet where we can formulate our biomaterial in real-time and ensure its homogeneity throughout long prints.

Once the printing process is finished, we can remove the pieces maintaining sterility.

Moreover, our projection system synchronizes with our industrial design software Cäster, printing its designs in real-time

Brick printing can be scaled to unprecedented extensions. To properly envision it’s manufacturing potential, at the largest scales kambium printers will be able to build the installed capacity of bioreactors worldwide for biopharma in one year.

-

29L

Effective printing volume

-

590 million

Print speed of 590M pixels per second

-

6 micron

Pixel size

-

983 million

Up to 983M pixels per layer