Introduction: The Revolution in Orbit

The story of space exploration has been written in metal, fire, and physics equations. We picture powerful rockets tearing through the atmosphere, astronauts planting flags on alien soil, and robotic rovers kicking up the red dust of Mars. But the next chapter, the one that sees humanity live beyond Earth, might be written in the language of DNA: biology.

Far from the challenges of launch dynamics and orbital mechanics, scientists inside the orbiting laboratories of the International Space Station (ISS) are confronting the bottleneck of deep space travel: how to sustain human life for months or years, far from any possibility of resupply. The answer, it turns out, lies in harnessing one of the oldest and most efficient factories known to science: living cells. This is the world of biomanufacturing: using engineered microbes, yeast, and animal cells (including human) as microscopic production plants to create everything from medicine and food to fuel.

This biological disruption could transform the paradigm of space travel, shifting our reliance from a fragile supply chain stretching millions of miles back to Earth to a model of self-sufficiency. This article reveals five impactful ways biomanufacturing is making long-term missions to the Moon and Mars possible and sustainable.

1: In Space, Weightlessness is a Feature

Microgravity Isn’t a Hurdle for Manufacturing

For decades, microgravity was seen as a problem to be overcome: it’s a force that weakens bones, atrophies muscles, and complicates even the simplest tasks. But for scientists in the field of biomanufacturing, this persistent weightlessness is an opportunity. On Earth, gravity introduces interference, causing problems like sedimentation and convection that can lead to imperfections in delicate biological processes. In orbit, with those forces removed, manufacturing can achieve a level of precision and quality impossible to replicate on the ground, even if we solved many challenges with traditional and revolutionary technologies alike.

Two key examples highlight this advantage:

Better Drugs: Creating stable and effective drugs often depends on growing protein crystals to understand their precise 3D structure. On Earth, gravity can create flaws in this process. In microgravity, proteins crystallize with greater uniformity and fewer defects. On the International Space Station, a major pharmaceutical company has researched to improve the formulation of a specific immuno-oncology drug. The goal was to produce ‘highly uniform, stable concentrated crystalline suspensions,’ a key challenge in formulating biologic drugs for easier administration on Earth. The results could lead to improved manufacturing and delivery for patients everywhere.

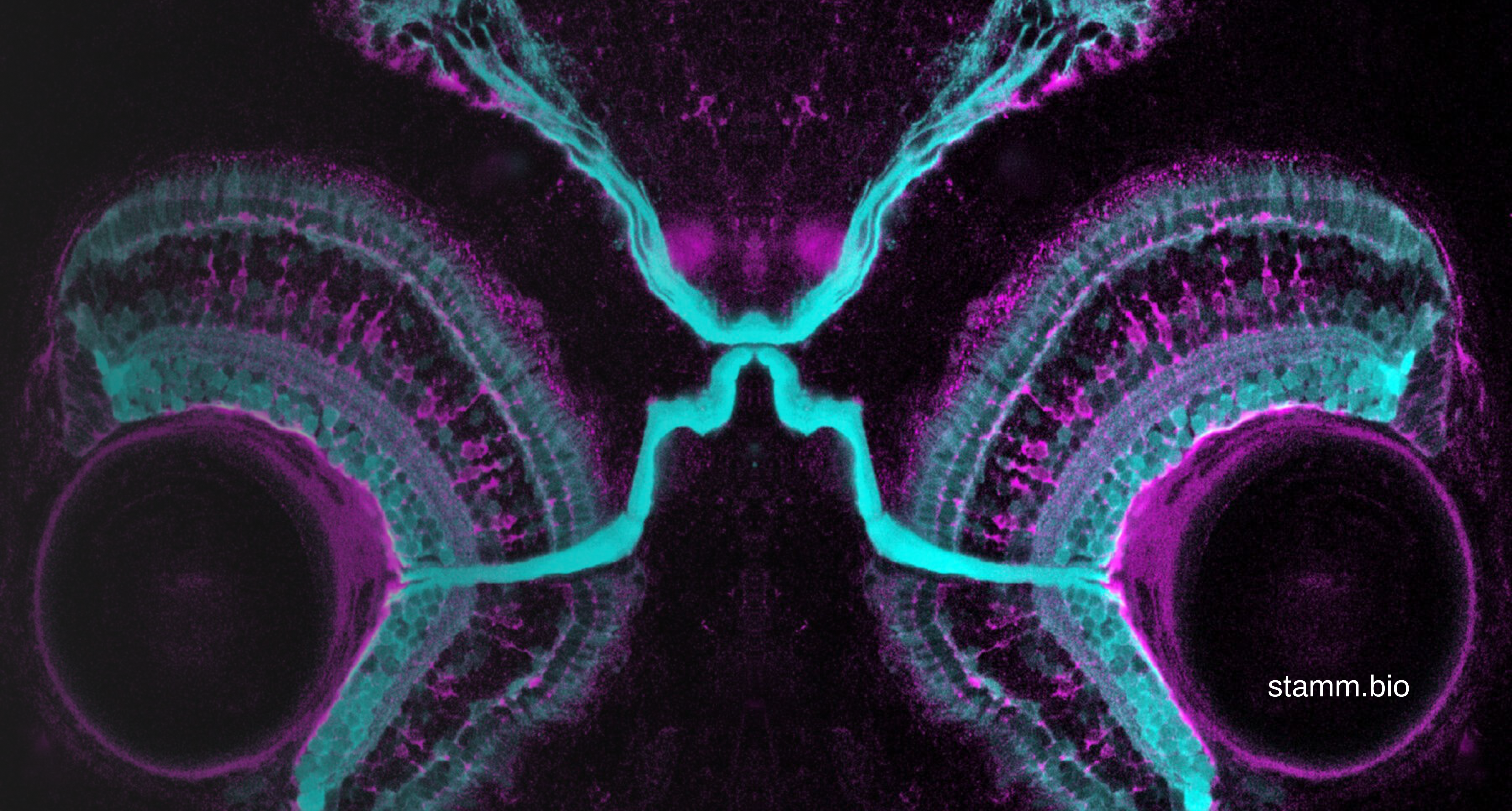

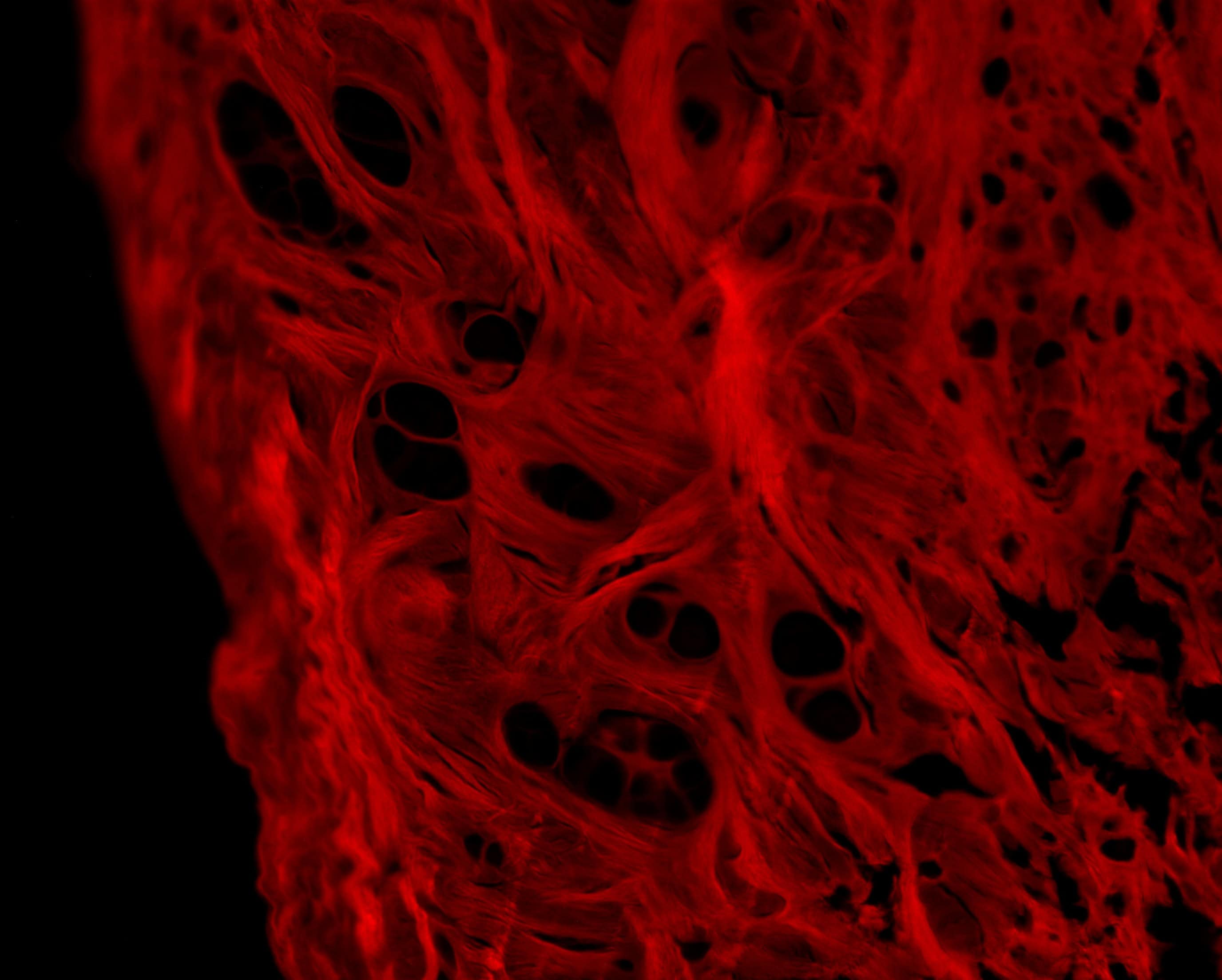

Advanced Human Tissues: The challenge of 3D bioprinting soft human tissues on Earth is that they tend to collapse under their own weight without artificial scaffolding. In microgravity, this limitation vanishes. The environment enables scaffold-free bioprinting, where cells can self-assemble into more physiologically relevant 3D structures like organoids and functional tissues. It also allows for the use of more fluidic, biocompatible bioinks that would be too soft to hold their shape on Earth. This is could be a game-changer for regenerative medicine, promising to accelerate the development of transplantable tissues for patients on Earth and provide better medical solutions for astronauts on long missions.

2: The On-Demand Space Pharmacy

Future Astronauts Could Be Farmers, Pharmacists, and Factory Workers

A mission to Mars could last for years, with no possibility of resupply from Earth. Pre-packaged food and medicine degrade over time, losing vital potency (and have a limited supply). If a critical component breaks, there’s no workshop to order a spare part from. The solution is to turn the spacecraft itself into a factory, capable of producing essential supplies on demand using engineered cells as the workforce.

A long-term experiment conducted on the space station serves as a prime example of this principle. Over a five-year study, astronauts tested a system that uses genetically engineered baker’s yeast stored in dehydrated packets. By simply adding water, the yeast is activated to produce essential antioxidants within 48 hours. This process creates critical nutrients that are normally found in vegetables but tend to degrade in pre-packaged mission food.

This “just add water” approach can be extended to an incredible range of products, including plastics for 3D printing, fuels, vitamins, and other pharmaceuticals. This transforms the astronaut’s job description: less test pilot, more off-world homesteader, actively cultivating the very means of their survival.

“We have a long-term goal of having microbes use essential resources in space so that astronauts can efficiently create food, medicine, fuel, and structural elements directly, without costly resupply missions from Earth.”

— Dr. Amor Menezes, an Associate Professor in the Department of Mechanical and Aerospace Engineering at the University of Florida

3: Space as a Time Machine for Medical Research

Spaceflight Is an Unparalleled Laboratory for Studying Aging and Disease

One of the discoveries from human spaceflight is how the body responds to the absence of gravity. Astronauts experience quick physiological changes that uncannily mimic the progression of age-related diseases on Earth, but at a vastly accelerated rate. These changes include rapid bone density loss similar to osteoporosis, significant muscle atrophy, and suppression of the immune system.

While these effects are a serious concern for astronaut health, they also present a unique research opportunity. The ISS has become an invaluable platform for studying the mechanisms of aging and disease. This compression of time allows scientists to observe the entire arc of a disease’s progression and test interventions in months, a process that would require decades-long studies on Earth. Researchers are sending “tissue chips” and organoids (miniature, 3D models of human organs) to the ISS to study these processes in detail and test new drugs, providing data that could lead to breakthrough treatments for patients back home.

This accelerated model of human biology is invaluable; the key to sustainability lies in studying our bodies and redesigning the resource systems that support them in space.

4: Yesterday’s Trash Will Be Tomorrow’s Treasure

Mission Waste as a Primary Resource

On a multi-year journey, waste (from plastic packaging to human metabolic waste) is a storage problem and a critical loss of resources. To achieve sustainability, long-duration missions must adopt the principles of “loop-closure” (LC) and “in-situ resource utilization” (ISRU), which mean recycling everything and living off the land.

A process called “alternative feedstock-driven in-situ biomanufacturing” (AF-ISM) shows how. Research proved that a viable growth medium for microbes could be created from mission byproducts and local resources. The recipe included:

- Post-consumer plastic waste (PET).

- Anaerobically pretreated fecal waste.

- Martian and Lunar regolith simulants, specifically Mars Global Simulant (MGS-1) and lunar simulants BP-1 and JSC-1/1 A, as a mineral source.

In the experiment, a microbe named Rhodococcus jostii successfully grew on this alternative medium and used these waste ingredients to produce lycopene, a valuable nutritional supplement.

The system produces a nutritional supplement that, as noted earlier, is beneficial for bone health and directly counteracts the accelerated osteoporosis that makes spaceflight so dangerous. The problem and its solution are contained within the same biological loop. This reduces the amount of material that needs to be launched from Earth, the biggest constraint and cost factor in space exploration.

5: Solving for Mars Could Help Earth

The Blueprint for Surviving on Mars is Also a Blueprint for a Sustainable Earth

These innovations shouldn’t be considered as isolated solutions. They can be components of a single, powerful blueprint for survival under extreme resource scarcity. The extreme constraints of a Martian habitat (limited power, no resupply, and a need to recycle every atom) force the development of hyper-efficient, sustainable, closed-loop systems. These are the very same systems needed to solve some of the most pressing environmental challenges back home.

The parallels are direct; we can learn from this blueprint:

- Waste Valorization: Turning plastic and organic waste into valuable products is a good model for creating a circular economy on Earth and tackling the global plastic pollution crisis.

- Carbon Capture: Designing systems to convert carbon dioxide from the Martian atmosphere into feedstock for biomanufacturing applies to carbon capture and sequestration technologies needed to combat climate change.

- Sustainable Manufacturing: The drive for low-energy, efficient, and eco-friendly biomanufacturing in space provides a powerful alternative to traditional, resource-intensive industrial methods on our planet.

The technologies we must invent to become Martians are, it turns out, the same technologies we must perfect to remain Earthlings.

Conclusion: The Future is Biological

The iron-and-rocket age of space exploration got us to the front door of the cosmos. But it is the bio-revolution that will unlock it, transforming barren outposts into living, breathing extensions of our own biosphere. Harnessing the power of cells to create self-sustaining ecosystems is the key to establishing a permanent human presence beyond our home planet.

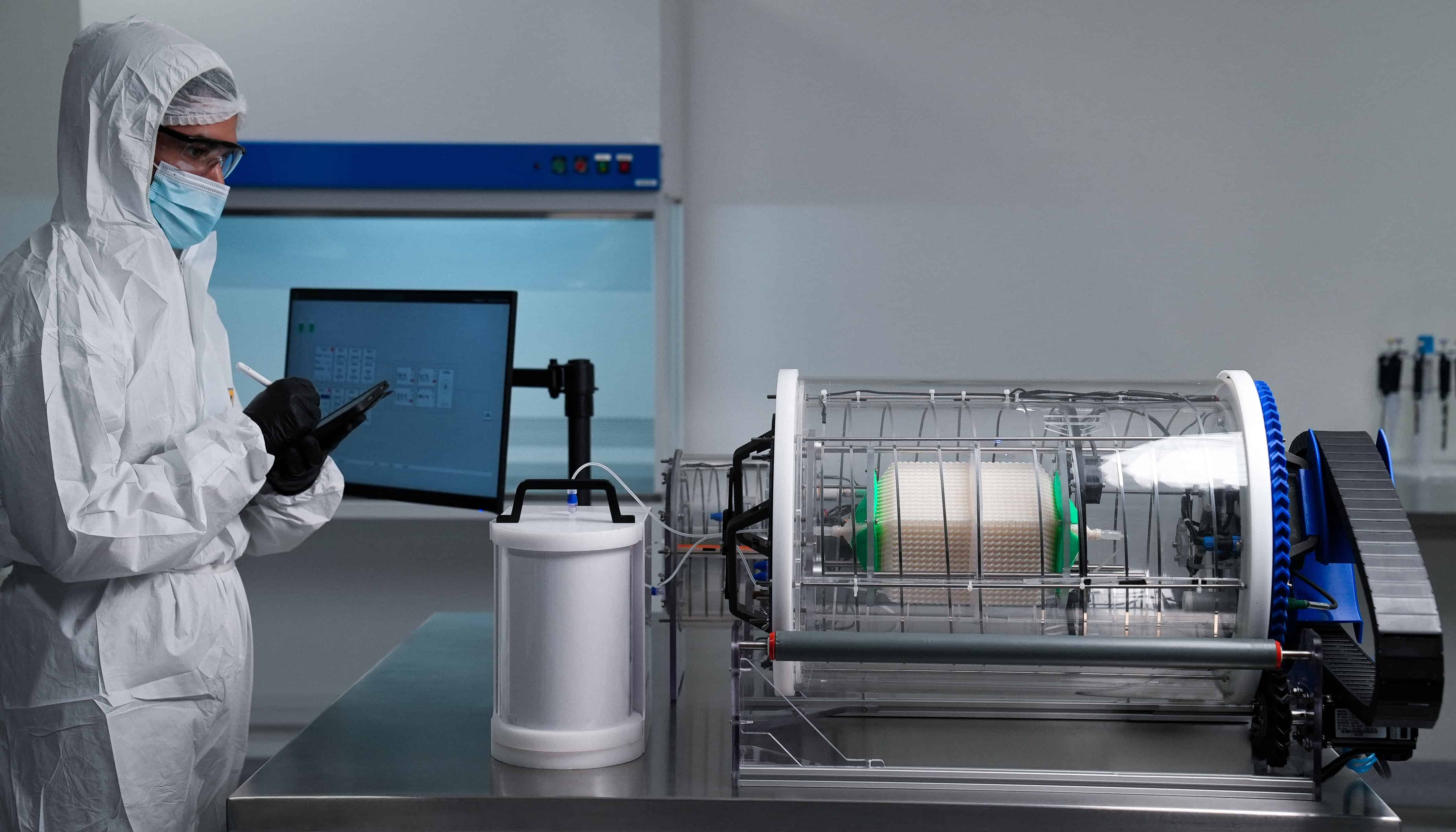

At the heart of this space-bound biorevolution is a powerful question: how do we scale biology itself? That’s where Stämm enters the conversation. With its nature-inspired approach to bioprocessing and compact, decentralized biomanufacturing platforms, Stämm is designing systems that could thrive both in cleanrooms on Earth and in cramped, energy-limited environments of orbit or Martian outposts. By eliminating bulky stainless-steel infrastructure and replacing it with microfluidic-inspired designs, Stämm’s technology embodies the same principles needed for space-based production: low-resource, closed-loop, and modular. What is a solution for democratizing biotech on Earth (bringing pharma-grade production to hospitals, farms, or underserved regions) becomes a blueprint for sustaining life beyond Earth.

This new frontier of biomanufacturing enables our journey to the stars and generates solutions for some of our greatest challenges on Earth. As we engineer these incredibly efficient, zero-waste life support systems to survive on other worlds, what’s our excuse for not implementing them here at home?